What We Offer

At Melbourne Welding Inspections, we specialise in providing high-quality inspection, compliance, and consulting services tailored to the structural, mechanical, and piping (SMP) sectors. Drawing on decades of practical industry experience, our team is equipped to support a wide range of construction, fabrication, and maintenance projects.

Welding Inspection

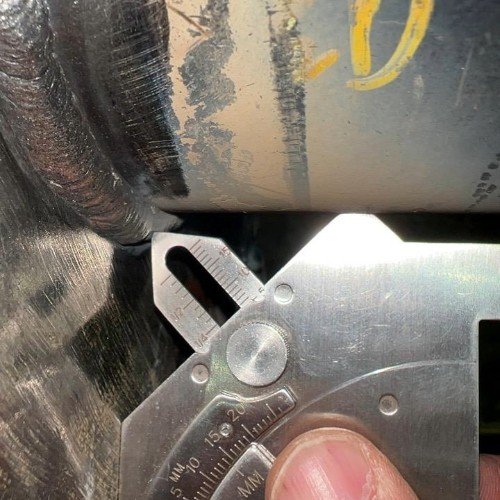

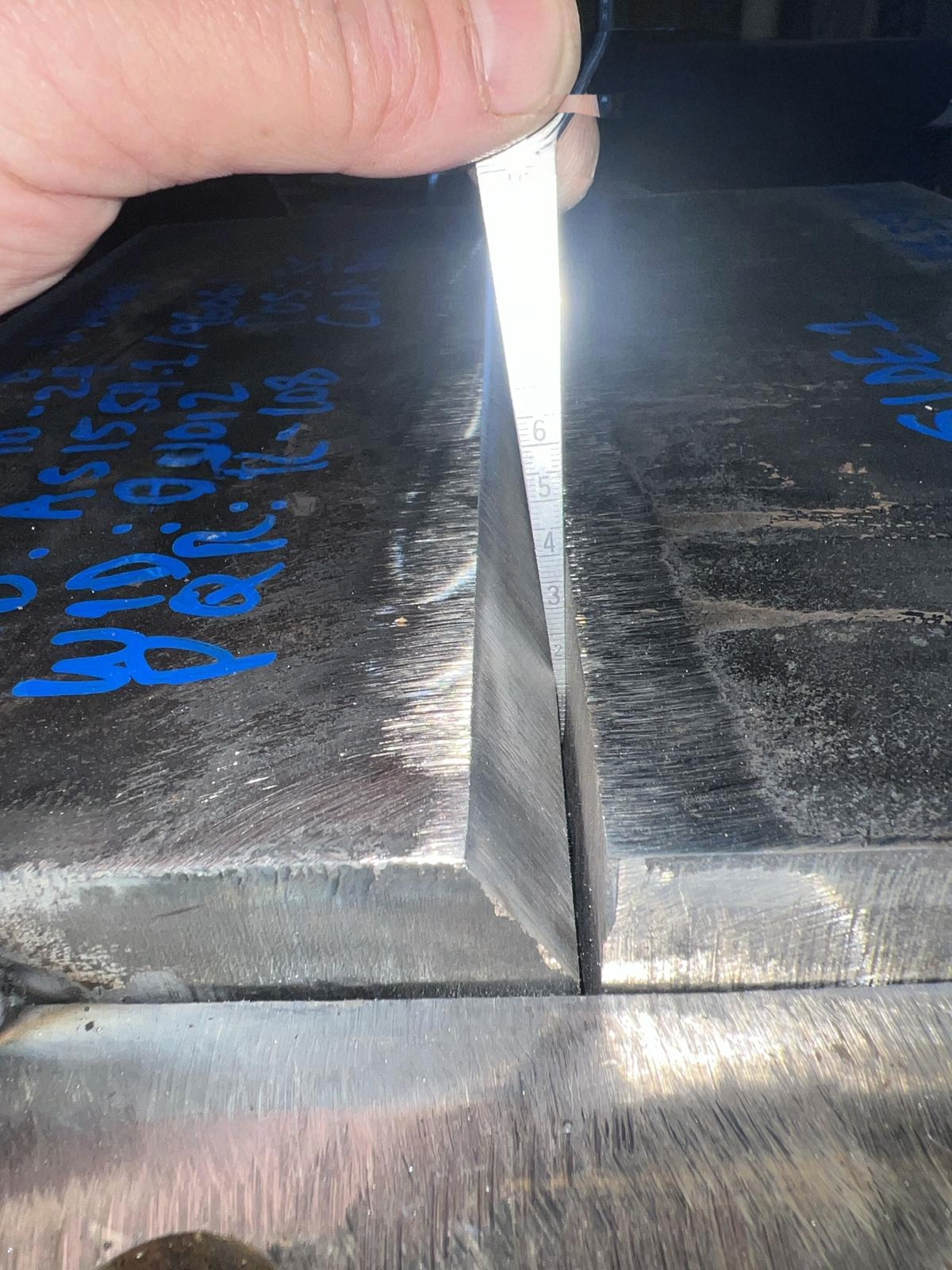

At Melbourne Welding Inspections, we deliver dependable, standards-driven welding inspections to verify welds for safety, performance, and compliance. Our inspectors are skilled in a variety of Australian and international codes—including AS/NZS, ISO, ASME, API, and AWS.

We offer visual inspections, NDT coordination, and document reviews to keep your welding operations precise, traceable, and project compliant.

Welder Qualification Testing

At Melbourne Welding Inspections, we provide comprehensive welder qualification services to ensure your personnel meet the highest standards of competency, compliance, and performance across all structural and piping applications.

-

Welder Testing & Certification

Qualification of welders to AS/NZS, ISO, ASME, and other relevant standards.

Supervised weld testing by qualified AS 1796 & AS 2214 Welding Supervisors, with full documentation and traceability.

On-site or workshop-based testing options available.

Renewal and revalidation of existing qualifications.

Visual inspection and NDT as required.

Welding Supervision

Melbourne Welding Inspections delivers expert welding supervision services that comply with a broad spectrum of Australian and international standards, including ISO, ASME, API, and AWS. Our experienced welding supervisors are dedicated to ensuring all welding and associated operations are performed with precision, prioritising safety and compliance throughout every phase of your Works.

-

We recognise the importance of thorough checks before, during, and after welding within the fabrication and welding stages. These checks are essential to control the Fabrication and Welding & to ensure the structural integrity of the products.

-

Our team brings a wealth of technical and industry experience to every site, applying their knowledge to ensure all welding activities meet required specifications and adhere to the highest quality standards. With Melbourne Welding Inspections, you can be confident your project will remain compliant, efficient, and reliable from start to finish.

Welding Procedure Development

At Melbourne Welding Inspections We understand that effective welding procedures are the foundation for producing consistent, high-quality welds. Our team specialises in developing and qualifying welding procedures to comply with both Australian and international standards, including AS/NZS, ASME, API

Working closely with your project team, we assess specific requirements including essential variables, material types, and intended service conditions. Our process includes drafting comprehensive Welding Procedure Specifications (WPS) and conducting Procedure Qualification Records (PQR) to ensure that every procedure is validated and tailored to your nominated standards and specifications.

By engaging our welding procedure development services, you gain confidence in your welding and fabrication processes. We provide detailed documentation and transparent reporting, ensuring every procedure is traceable and meets all standard, specification, and client design expectations.

QA/QC Surveillance Services

At Melbourne Welding Inspections, we specialise in providing top-tier Quality Assurance (QA) and Quality Control (QC) surveillance services for welding and fabrication projects across Melbourne and Victoria. Our experienced inspectors are committed to ensuring your projects meet all relevant Australian standards, client specifications, and regulatory requirements.

-

Welding Inspection: Detailed assessment of weld quality, including visual inspections, non-destructive testing (NDT), and verification of welding procedures and qualifications.

Documentation Review: Thorough evaluation of welding documentation, including Welding Procedure Specifications (WPS), Procedure Qualification Records (PQR), welder qualifications, Coating ITR’s and Manufacturer Data Reports.

Compliance Monitoring: Ongoing surveillance to ensure adherence to project specifications, Australian & International Standards.

Pre-Inspection Meetings: Coordination with project teams before fabrication or erection to clarify requirements and expectations.

In-Process Surveillance: Regular site visits during fabrication and construction to monitor welding activities, material traceability, mechanical equipment inspections, flange management inspections, Part-Turn Bolt tensioning splice Inspections, coating surveillance and compliance with approved procedures to specifications, standards & design.

Final Inspection & Handover: Comprehensive end-of-project inspections, completions systems, punch-list management, and preparation of final quality dossiers for client handover.

-

Certified Inspectors: Our team holds local & internationally recognised certifications such as CSWIP, AMPP /NACE & AS 1796/2214 Certificate 10 - Welding Supervisors, Lead Auditors and brings years of industry experience.

Unbiased Reporting: Independent, transparent, and detailed inspection reports delivered promptly after every visit.

Responsive Service: Fast turnaround for urgent site attendance across Melbourne and regional Victoria.

Custom Solutions: Tailored QA/QC surveillance programs to suit your project’s size, complexity, and timeline.

Safety First: Strict adherence to occupational health and safety requirements on every site.

-

Construction - (*Vic-Roads Projects excluded)

Oil & Gas

Mining & Resources

Manufacturing

Power Generation

Transport & Rail

Quality Consulting Services for Accreditations

Melbourne Welding Inspections delivers comprehensive consulting services designed to support fabrication and welding companies in attaining ISO 3834 and AS/NZS 5131 accreditations. Our team has established a strong track record, having successfully guided numerous organisations through the process of achieving these key certifications and realising excellent results.

-

Our specialists work closely with your organisation to develop and implement detailed procedures, registers, systems, work instructions, and safe operating procedures. These systems are customised to suit your business requirements, ensuring a practical and effective approach to quality management.

-

We focus on the seamless integration of all quality management processes into the ISO 9001 Quality Management Framework. This approach helps your organisation maintain robust, compliant quality systems and achieve certification-grade outcomes that meet industry standards.

-

In Victoria, the Department of Transport updated Section 630 in July 2022, revising specifications to require all fabrication and site welding companies working on Vic Roads projects to hold both ISO-3834.2 and AS/NZS 5131 accreditations. Melbourne Welding Inspections ensures your business remains compliant with the DEPT Sec 630 specification requirements, supporting you in successful participation on Vic Roads projects.